ENHANCING THE VALUE OF PRODUCT with

Superior Thermal Packaging with a Remarkable Sustainability Story

The Renewable, Sustainable Temperature-Control System for Packaging & Shipping

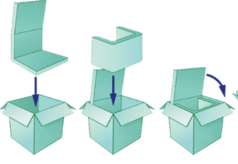

ThermoPod’s® innovative, eco-and-user-friendly products are ideal for today’s temperature-control and protective packaging markets. Freight can be expensive, however, the fact that our products ship collapsed and slightly compressed make them more affordable. Additionally, they are user-friendly, biodegradable, recyclable and, in many applications, compostable. ThermoPod®, LLC., offers a variety of insulation solutions specifically designed with ultra-insulating padding made from select, purified, enhanced fibers that are highly absorbent for the containment of undesirable condensation or product leakage.

Where it all Began...

ThermoPod®…A Game-Changer

Our innovative invention, the original ThermoPod® temperature-control and protective packaging system [U.S. Patent No. 6,875,486], finished first runner-up in a national competition, sponsored by INDA, at the Research, Innovation & Science for engineered Fabrics Conference, in Baltimore, MD.

The Next Phase...

ThermoKeepers® are cost-effective, ecological, two-piece fiber insulating liners that replace expanded polystyrene 6-piece inserts and 1-piece tubs. Outdated, petroleum-based foam applications require expensive dies, have limited cushioning, and zero absorption properties. Unlike EPS, our material will neither chip nor crack, which ensures that there will be ZERO shrinkage of either packaging or cargo.

Importantly, EPS is not biodegradable, compostable nor entirely suitable for re-use.

A Brief History...

We entered the cold-chain and protective packaging market in 1999.

Our goal was/is to service those industries with innovative, sustainable products that are user-and-environmentally-friendly, yet cost effective.

Our unique business model, based on patents and other IP, allows us to outsource our manufacturing to multiple, strategically located, ISO 9000 certified suppliers in the USA and Mexico.

This eliminates the need for “brick and mortar“, capital intensive equipment, employees, inventory, etc; It also enables us to invoice and ship direct. Multiple locations mean cutting freight costs – because we are never far from a given client!

All of this saves you money!

Changing The Future of Packaging

Unlike EPS foam manufacturers, we do not have to charge customers for expensive dies.

Our natural fiber insulation liners can be cut to any size by simply moving the cutter(s), eliminating the need/expense for holding stock.

We are now a “one-stop-shop“, supplying all your packaging needs from Thermopod Mailers, to ThermoKeeper Shippers to EZ ThermoPallet Covers.

Unlike other “green” competitors we excel at shipping with gel packs or dry ice – our insulative product will not deteriorate from condensation – it is simply wicked away.

The Best is Yet to Come

Be sure to check out our “Technologies” and “New Concepts” sections, for:

– Our proprietary EZ ThermoCard Technology…

– Our patent-pending Robotically Fulfilled, One-Piece Insulated ThermoShipper, and;

– Our patent-pending Natural Fiber Based Rigid Foam Substitute.

Six Ways Our Products Enhance Your Bottom Line

Some of Our Past & Present Customers